Electric vehicle collision repair requires specialized expertise beyond traditional auto body work. Electric vehicles such as Tesla, Rivian, and Lucid use high-voltage systems and specialized materials. Manufacturer certification and strict safety procedures are required when working on them. Even small damage can affect the battery and overall safety. Certified repair centers with the right tools for aluminum welding and battery diagnostics complete repairs according to manufacturer standards.

In Central Florida, the number of electric vehicles on the road continues to grow. Choosing a certified collision repair facility helps protect the vehicle’s warranty and resale value. Windermere Collision Center provides services supported by factory-trained technicians, dedicated EV repair bays, and direct access to OEM parts. Selecting Windermere keeps repairs aligned with manufacturer protocols and supports long-term vehicle performance.

Why Your EV Can’t Go to Just Any Collision Center

Electric vehicle collision repair is different from standard auto repair because of the specific safety and technical requirements involved. High-voltage systems in EVs present hazards that need specialized training and equipment to handle properly.

High-Voltage Safety Requirements

EV repair work involves electrical systems operating at 400-800 volts, far exceeding the 12-volt systems found in traditional vehicles. This voltage level can cause serious injury or death if handled improperly.

Certified collision repair centers must implement strict safety protocols:

- High-voltage disconnect procedures before any repair work begins

- Specialized personal protective equipment for technicians

- Lockout/tagout procedures for electrical systems

- High-voltage testing equipment to verify system safety

- Emergency response procedures for electrical incidents

Specialized Training and Certification Requirements

Technicians performing electric vehicle collision repair must complete manufacturer-specific training programs that cover electrical safety, battery systems, and unique repair procedures.

These programs require significant time and financial investment:

| Training Category | Duration | Cost Range | Recertification |

| High-Voltage Safety | 40+ hours | $2,000-$5,000 | Annual |

| Manufacturer-Specific | 80+ hours | $5,000-$15,000 | Bi-annual |

| Advanced Diagnostics | 40+ hours | $3,000-$8,000 | Annual |

Unique EV Construction and Materials

Electric vehicles use construction methods and materials significantly different from traditional vehicles. These differences affect every aspect of collision repair services:

Structural Differences:

- Aluminum space frames requiring specialized welding techniques

- Battery pack integration affecting structural integrity

- Different crash energy management systems

- Unique mounting points for electrical components

Material Challenges:

- Advanced high-strength steels requiring specific repair procedures

- Carbon fiber components in performance EVs

- Specialized adhesives and sealants for battery protection

- Thermal management materials requiring careful handling

Battery System Considerations

The battery pack represents the most complex and expensive component in any EV. Collision damage affecting battery systems requires immediate professional assessment by a certified collision repair center. Battery-related damage can compromise vehicle safety and performance in ways that may not become apparent until weeks or months after an accident.

Battery system damage evaluation requires advanced diagnostic tools and specialized training. Even small impacts may affect the battery pack, cooling components, or high-voltage connections. Technicians with training in electric vehicle collision repair, such as those at Windermere Collision Center, are qualified to inspect and repair these systems properly.

Understanding EV-Specific Collision Damage

Electric vehicle collision repair starts with understanding how these vehicles respond differently compared to gas-powered models. Their construction and placement of components create unique damage patterns that call for specialized inspection and repair methods.

High-Voltage System Integrity Assessment

After any collision involving an EV, the integrity of high-voltage systems must be verified before the vehicle can be safely handled or repaired. This assessment requires specialized diagnostic equipment and training that only certified facilities possess.

Critical Assessment Areas:

- Battery pack housing and mounting systems

- High-voltage cable routing and protection

- Inverter and motor housing integrity

- Charging system components and connections

- Thermal management system damage

Battery Pack Vulnerability and Protection

Most EV battery packs are built with strong protection systems, but collision forces can still affect these safeguards in hidden ways. Professional evaluation is important because battery damage is not always visible or detectable through routine diagnostics.

Signs Requiring Immediate Professional Evaluation:

- Any visible damage to the vehicle’s undercarriage

- Battery warning lights or error messages

- Unusual odors or visible vapor from the vehicle

- Charging system malfunctions or reduced range

- Changes in vehicle handling or noise levels

Structural Considerations Unique to EVs

EV structural design uses the battery pack as part of the structure. This creates distinct load paths and energy absorption patterns. Collision repair technicians must know these design factors to restore structural integrity.

The battery pack mounting system spreads crash forces through the vehicle frame. Damage to these mounting points or nearby structural parts can reduce protection for the battery pack and weaken overall safety performance. Collision repair centers with EV-specific training are equipped to evaluate and repair these structural components correctly.

When Professional Assessment Becomes Critical

Certain collision scenarios require immediate evaluation by a certified collision repair center regardless of apparent damage severity:

- Any impact affecting the vehicle’s undercarriage or battery area

- Collisions involving side impacts near charging ports

- Accidents resulting in airbag deployment

- Impacts causing electrical system warning messages

- Situations where the vehicle cannot charge properly after an accident

Attempting to drive an EV with potential high-voltage system damage creates serious safety risks. Professional assessment ensures both immediate safety and long-term vehicle reliability.

What Manufacturer Certification Really Means for EV Repair

Manufacturer certification for electric vehicle collision repair represents far more than a marketing credential. These programs require substantial investments in equipment, training, and facility modifications that directly impact repair quality and safety.

Tesla, Rivian, and Lucid Certification Requirements

Each EV manufacturer maintains specific requirements for authorized collision repair centers. These requirements reflect the unique characteristics and repair needs of their vehicles.

Tesla Certification Requirements:

- Dedicated aluminum repair bay with specialized equipment

- Tesla-specific diagnostic and calibration tools

- Certified technician training and ongoing education

- Parts ordering and inventory management systems

- Quality control procedures meeting Tesla standards

Rivian and Lucid Requirements:

- High-voltage safety equipment and procedures

- Manufacturer-specific repair documentation access

- Advanced diagnostic capabilities for proprietary systems

- Specialized tooling for unique components

- Direct communication channels with engineering teams

Training and Equipment Investments

Becoming a certified collision repair center for electric vehicles requires a large financial investment. These investments allow facilities to safely and properly service EVs in line with manufacturer specifications.

| Investment Category | Cost Range | Purpose |

| High-Voltage Equipment | $50,000-$150,000 | Safety testing and diagnostic tools |

| Specialized Tooling | $100,000-$300,000 | Manufacturer-specific repair equipment |

| Facility Modifications | $200,000-$500,000 | Safety systems and dedicated work areas |

| Training Programs | $50,000-$100,000 | Initial and ongoing technician certification |

Access to Technical Documentation and Support

Certified collision repair centers, like Windermere Collision Center, receive access to detailed repair procedures, technical service bulletins, and direct support from manufacturer engineering teams. This information proves crucial for complex repairs that may not be covered in standard repair manuals.

Documentation Benefits:

- Step-by-step repair procedures for specific models

- Safety protocols for high-voltage system work

- Parts identification and sourcing information

- Quality control checkpoints and verification procedures

- Updates on new repair techniques and safety requirements

OEM Parts Availability and Sourcing

Certified facilities maintain direct connections with manufacturers for parts sourcing. This access allows them to obtain genuine OEM parts quickly and helps reduce repair timelines compared to facilities that depend on third-party suppliers.

OEM parts for EVs often incorporate safety features and specifications not available in aftermarket alternatives. Using genuine parts maintains warranty coverage and ensures proper system integration with the vehicle’s complex electronic systems.

The EV Repair Process: What to Expect

Electric vehicle collision repair follows a structured process designed to ensure safety while maintaining the vehicle’s sophisticated systems. Understanding this process helps EV owners set appropriate expectations and make informed decisions about repair services.

Safety Protocols and Initial Assessment

All EV collision repair begins with comprehensive safety protocols. Before any repair work commences, technicians must safely disconnect high-voltage systems and verify that all electrical hazards have been eliminated.

Standard Safety Procedures:

- High-voltage system shutdown and lockout

- Battery isolation and testing procedures

- Work area preparation with safety equipment

- Personal protective equipment verification

- Emergency response preparation

The initial assessment phase involves comprehensive diagnostic testing to identify both visible and hidden damage. This assessment requires specialized equipment capable of communicating with the vehicle’s multiple computer systems.

Parts Sourcing Challenges and Realistic Timelines

EV parts availability presents unique challenges compared to traditional vehicle repair. Many components are manufactured in limited quantities or require special ordering processes that can extend repair timelines.

Typical Timeline Factors:

- Battery pack components: 4-12 weeks

- Body panels and structural elements: 2-8 weeks

- Electrical components and sensors: 3-10 weeks

- Interior and trim pieces: 2-6 weeks

Windermere Collision Center maintains relationships with multiple suppliers to minimize parts delays. However, EV owners should expect longer repair times compared to traditional vehicles due to parts complexity and availability limitations.

Insurance Coordination for EV Repairs

EV collision repair requires extensive coordination with insurance companies to secure proper authorization for specialized procedures and parts. Many insurance adjusters lack familiarity with EV repair requirements, making this coordination particularly important.

Insurance Considerations:

- Pre-authorization for high-voltage system work

- Explanation of specialized equipment and procedures

- Documentation of manufacturer-required repair methods

- Parts cost justification for OEM components

- Extended rental car coverage for longer repair times

Quality Control and Post-Repair Testing

EV collision repair concludes with comprehensive testing to verify that all systems function properly. This testing goes far beyond traditional repair verification and requires specialized diagnostic equipment.

Testing Procedures Include:

- High-voltage system integrity verification

- Battery pack performance testing

- Charging system functionality checks

- Electronic system calibration verification

- Road testing under various operating conditions

Insurance Considerations for EV Collision Repair

Insurance coverage for electric vehicle collision repair involves unique considerations that traditional vehicle owners rarely encounter. Understanding these factors helps EV owners navigate the claims process and ensure proper repair coverage.

Working with Insurance Adjusters on EV Claims

Many insurance adjusters have limited experience with EV collision repair requirements. This knowledge gap can lead to coverage disputes or inadequate repair authorizations that compromise repair quality.

Key Communication Points:

- Explanation of EV-specific safety requirements

- Documentation of manufacturer repair procedures

- Justification for specialized equipment and training

- Timeline expectations for parts availability

- Cost differences compared to traditional repairs

Windermere Collision Center coordinates with insurance companies to inform adjusters about specific EV repair needs. This approach supports timely approval and helps avoid coverage issues that may slow down the repair process.

Understanding EV Repair Cost Factors

EV collision repair typically costs more than traditional vehicle repair due to specialized requirements, equipment, and parts. Understanding these cost factors helps set appropriate expectations and supports insurance discussions.

Cost Factor Categories:

- Specialized labor rates for certified technicians

- High-voltage safety equipment and procedures

- OEM parts premium over traditional alternatives

- Extended diagnostic and testing procedures

- Additional safety protocols and documentation

Ensuring Proper Repair Procedures Are Followed

Insurance companies may pressure repair facilities to use less expensive repair methods or aftermarket parts. EV owners must understand their rights and the importance of manufacturer-approved procedures.

Critical Coverage Areas:

- OEM parts vs. aftermarket alternatives

- Manufacturer-certified repair procedures

- High-voltage system testing and verification

- Post-repair calibration and testing

- Extended warranty coverage protection

Working with a certified collision repair center ensures that proper procedures are followed, regardless of insurance pressure. This approach protects the vehicle’s warranty, safety, and resale value.

Choosing the Right EV Collision Repair Partner

Selecting the appropriate EV collision repair services for your electric vehicle requires evaluating multiple factors beyond basic repair capabilities. The right partner combines technical expertise with customer service and communication skills.

Certification Verification and Validation

Begin your evaluation by verifying that the facility holds current certifications for your specific EV brand. Don’t accept general assurances about capabilities – request to see actual certification documents and confirm their validity.

Verification Steps:

- Review current certification documents

- Confirm technician individual certifications

- Verify equipment and tooling requirements

- Check facility safety systems and procedures

- Validate ongoing training and education programs

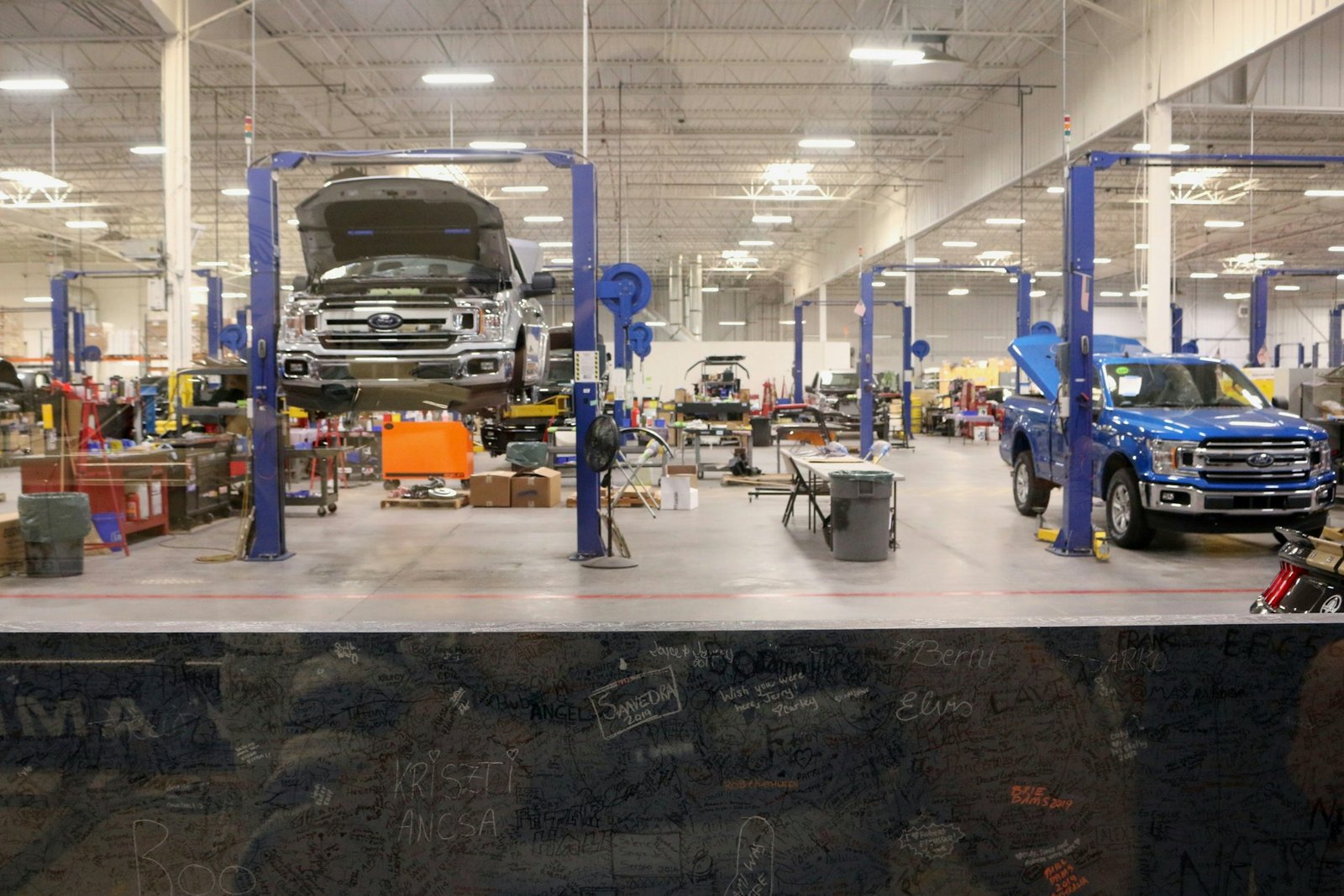

Facility and Equipment Assessment

Tour the repair facility to assess their capabilities and commitment to EV repair work. Look for dedicated work areas, specialized equipment, and safety systems specifically designed for electric vehicle collision repair.

Assessment Criteria:

- Dedicated EV repair bays with proper safety equipment

- High-voltage testing and diagnostic tools

- Aluminum welding capabilities and clean work areas

- Parts storage and handling procedures

- Emergency response equipment and procedures

Customer Experience and Communication Standards

EV collision repair often involves extended timelines and complex procedures. Choose a facility that provides clear communication and manages customer expectations throughout the repair process.

Communication Expectations:

- Regular progress updates with photographic documentation

- Proactive notification of timeline changes or complications

- Clear explanation of repair procedures and requirements

- Insurance coordination and advocacy support

- Post-repair support and warranty coverage

Location and Convenience Factors for EV Owners

While technical capabilities remain the primary consideration, location and convenience services can significantly impact your overall experience during the repair process.

Practical Considerations:

- Reasonable proximity to home or work locations

- EV charging capabilities at the repair facility

- Rental vehicle coordination and availability

- Towing services familiar with EV safety requirements

- Flexible scheduling for busy professionals

Windermere Collision Center serves EV owners throughout Central Florida from our Winter Garden location. Our facility provides convenient access for customers from Orlando, Windermere, and surrounding communities while maintaining the specialized capabilities required for professional electric vehicle collision repair.

The combination of technical expertise, proper equipment, and customer-focused service creates the ideal environment for EV collision repair services. Choose a certified collision repair center that demonstrates commitment to both technical excellence and customer satisfaction.

Experience Central Florida’s Premier EV Collision Repair Facility

Don’t trust your electric vehicle to just any collision repair center. Windermere Collision Center specializes in electric vehicle collision repair with certifications from Tesla, Rivian, Lucid, and other leading EV manufacturers. Our Winter Garden facility features dedicated EV repair bays, high-voltage safety systems, and technicians trained specifically in electric vehicle collision repair.

As a certified collision repair center, we understand the unique requirements of EV collision repair services. From high-voltage safety protocols to manufacturer-specific repair procedures, our team provides the specialized expertise your electric vehicle demands.

Why Choose Our EV Collision Repair Services:

- Certified for Tesla, Rivian, Lucid, and major EV brands

- Dedicated high-voltage repair bays with safety systems

- Factory-trained technicians with ongoing EV education

- Direct OEM parts sourcing and inventory management

- Comprehensive insurance coordination and support

- On-site EV charging capabilities during repairs

Call (407) 554-2228 to schedule your EV collision repair consultation, or visit us at 933 Carter Road, Winter Garden, FL, 34787.

Serving electric vehicle owners throughout Winter Park, Windermere, Orlando, Heathrow, and surrounding Central Florida communities with specialized EV collision repair services.